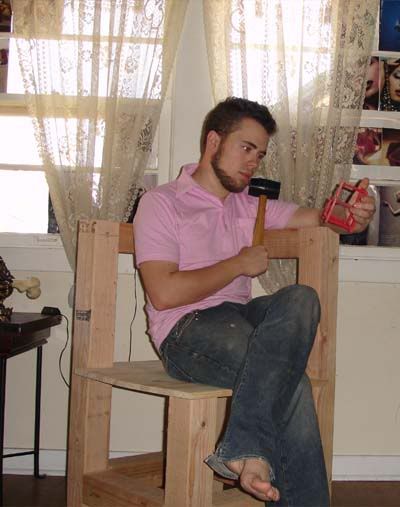

Now I say finished, but really the majority of the work is still ahead. It's load-bearing and not wobbly, but it's still quite rough.

More detailed pictures will come later, when there is actually attractive detail to show, but first it is necessary to explain the construction.

The three tallest posts, all out of rich Cascadian Douglas Fir, stand at 36 inches, the lower seat post stands at 18 inches, and the six support beams are 15 inches across. The seat is a 24x24x1 sheet of pine, providing something of a lip over the seating edge. This lip will probably be trimmed up quite a bit before I consider it done, but it works for now. You may notice a couple of extra plugs cut out of the top of the posts, and those will eventually be filled, hiding all evidence of my drill-happy ways. I used socket plugs and dowels to fix the chair together. Some of these are angled slightly so that it provides a little tension in the joints. The seat is likewise held up with dowels, though they simply run under the seat and hold it up.

I have a confession to make: though I cut everything with a small handsaw, I was forced to use a power drill to bore out the plugs. The experience was actually rather unpleasant, even though it was probably quite a bit more easily done than with hand tools. There's just something unnatural about power tools. There you are with sawdust all over you, sweat on your brow, a mallet and a saw in your hands; then suddenly you pick up a loud electric motor with a handle, and the tool-using ape-man inside you runs away. There's also the issue that I have a lot of sanding left to do, and why wouldn't I just use an electric sander?

However, this is I shall not do. Bad enough that I used one power tool, I'm not about to compound it. The thing I just don't get is how my measurements always come out so crappy. I try to be very precise, but I'm all thumbs.

The chair is, surprisingly, not very creaky. It creaks a little due to some sloppy joints that need a bit more drilling, but for being composed completely of wood, lacking any kind of glue or metal fastener, I think it came out pretty okay. I may add glue eventually, but for now it helps that I can disassemble it for moving, as it will quite likely stand, reassembled, in Portland on Monday night.

Go me.

PS: This chair should have been completed by 5th May, but due to the constraints of material transport, and the laziness of yours truly, it is a little bit late.

No comments:

Post a Comment